An industrial sugar mill rollers are used to crush sugarcane and extract maximum juice. Modern mills use three roller mill configuration, extended milling tandems and imbibition process to improve juice extraction. Accurate sugar mill structure and mill settings further helps to improve the mill’s efficiency. These include roller parts, materials, forces and nip distances. Furthermore, industrial sugar mill roller’s features, types improve the juice extraction. Mill owners should know when rollers require resurfacing or re-grooving along with the hard-facing techniques to increase the roller’s life.

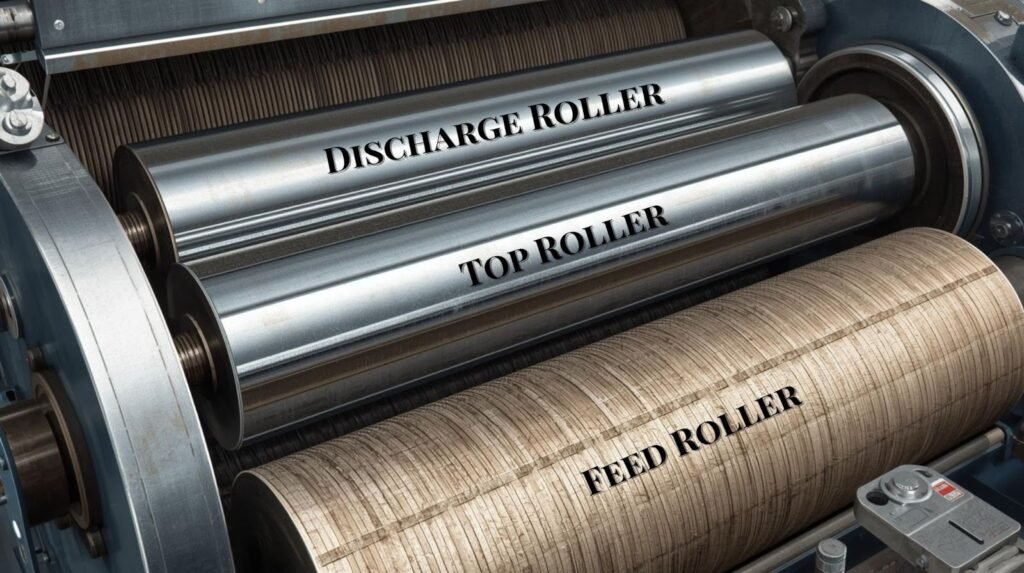

Three-Roller Mill Configuration

Three Roller Mill Configuration

Three roller mills consist of a top roller, feed roller, and discharge roller. It forms two nips for cane compression. This three-roller system applies sequential pressure to extract the maximum juice. Each roller works under specific torque and surface geometry. This ensures consistent feeding, squeezing, and drainage.

The Milling Tandem and Imbibition Process

The Milling Tandem and Imbibition Process

Multiple roller mills are arranged in a milling tandem. Here the bagasse from one mill feeds the next. It works like a cycle.

The imbibition process introduces water or juice into bagasse. It improves sucrose extraction by reabsorbing residual juice. In modern sugar mills, imbibition water flow increases the overall efficiency largely.

Performance Indicators in Sugar Milling

Performance Indicators in Sugar Milling

Industrial Sugar Mill Rollers Structure

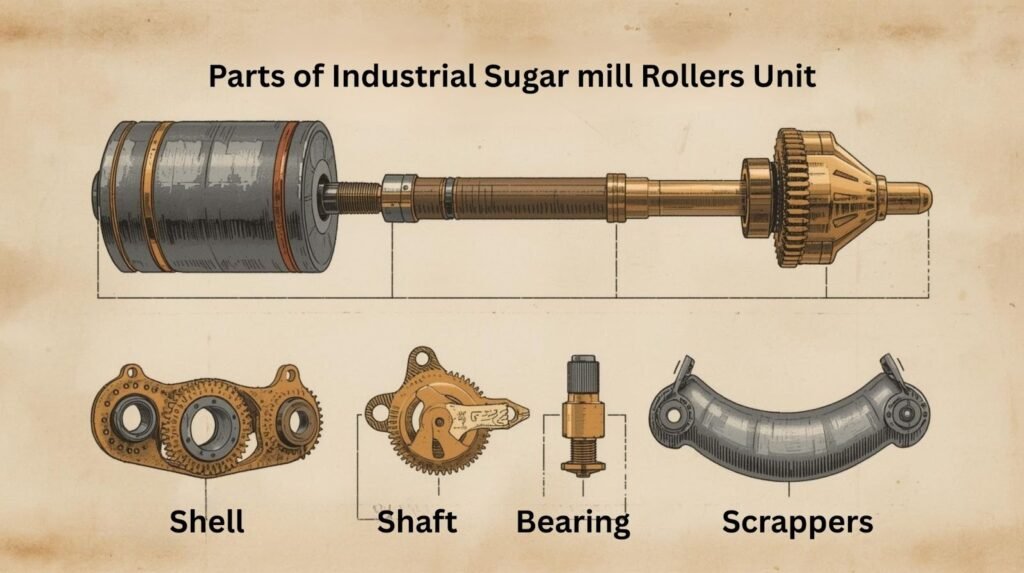

Parts of Industrial Sugar mill Rollers

Parts of Industrial Sugar mill Rollers

An industrial sugar mill roller’s assembly includes the shell, shaft, brass bearing housings, and scrapers. Accurate alignment of industrial sugar mill rollers prevents deflection and improves torque transmission efficiency.

Material for Industrial Sugar Mill Rollers

Material for Industrial Sugar Mill Rollers

Forged Steel for Shafts

Modern forged steel shafts use 42CrMo4 or EN24. They deliver high tensile strength. Furthermore, they handle torsional loads efficiently during peak crushing periods.

Cast Iron for Shells

Traditional cast iron shells offer good wear resistance and cost-effectiveness to industrial sugar mill rollers. The shell’s hardness typically ranges from 450–550 BHN, suitable for medium-duty milling operations.

Advanced Alloys (e.g., SRB) for Enhanced Performance

Special roller alloys use SRB, Ni-Hard, or high-chrome alloys for industrial sugar mill rollers. These materials increase shell hardness to 600–650 BHN. These alloys resist micro-pitting, corrosion, and abrasive wear, ensuring longer operational life under aggressive milling conditions.

Forces and Stress Analysis on Industrial Sugar Mill Rollers

Torsional Load and Drive Torque

The torsional load generated by the main drive transfers torque to each roller shaft. Finite element analysis (FEA) is now used for optimising shaft geometry and reducing stress concentrations.

Bending Stress and Hydraulic Crushing Load

Hydraulic loading systems apply uniform pressure to maintain the desired crushing force. They can range from 25–35 tons per roller. Proper roller geometry minimizes bending deflection under these loads.

Fatigue and Failure Mechanisms

Roller shafts fail by torsional fatigue, and the shells suffer from surface spalling or thermal fatigue. Advanced non-destructive testing, including ultrasonic and magnetic particle inspection, helps detect early fatigue cracks before catastrophic failure.

Industrial Sugar Mill Roller’s Features

Roller Surface Grooving

Grooved Sugar Mill Roller

Grooving Parameters

Modern grooving uses optimized pitch and helix angles of 20–35° to improve cane gripping. Shallow grooves reduce wear, while deeper grooves increase penetration in high-fiber cane.

V-Grooves vs. U-Grooves

V-grooves ensure better juice drainage. On the other hand U-grooves provide greater gripping area for high moisture cane. The choice depends on the cane variety and fiber percentage.

Messchaert Grooves for Drainage

Messchaert-type grooves are designed with multi-angled channels. They help improve the drainage flow paths, preventing juice reabsorption and reducing bagasse moisture.

Specialized Roller Types

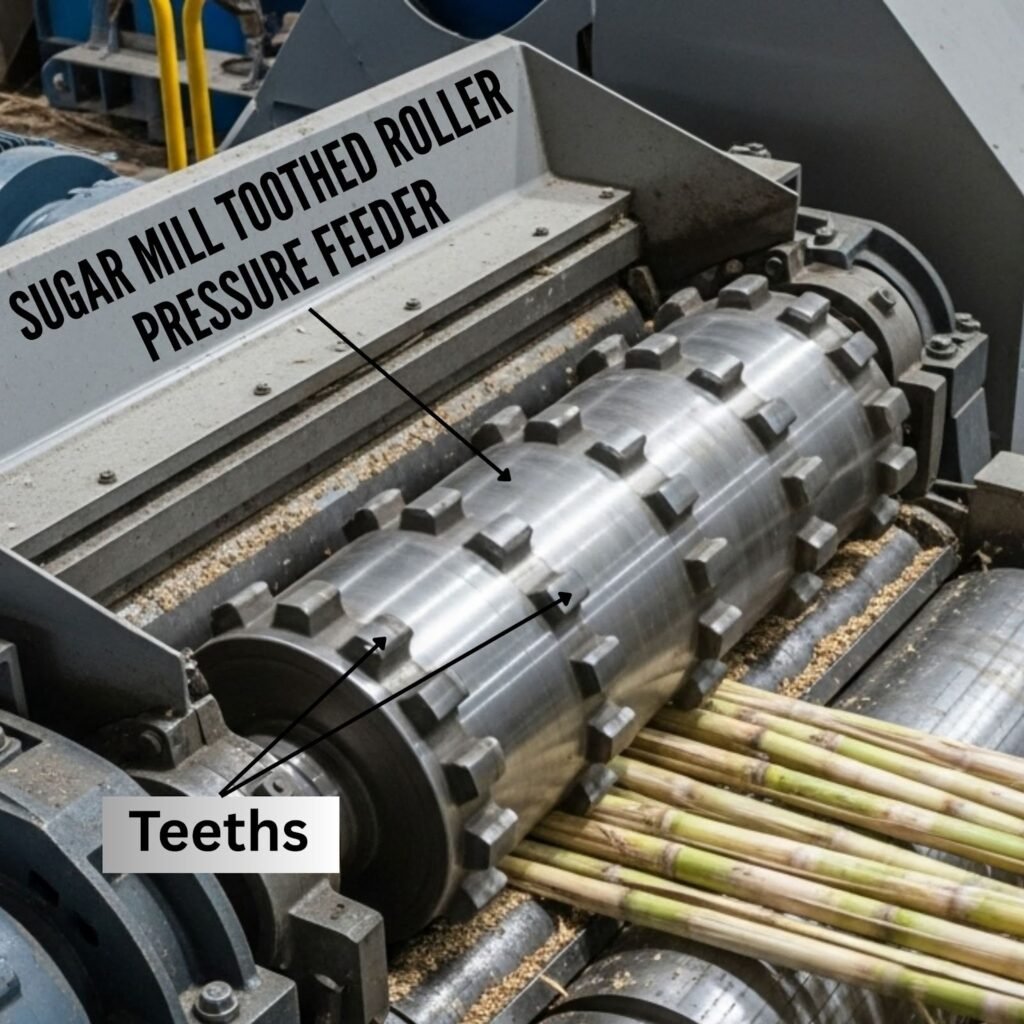

Toothed Roller Pressure Feeders

Toothed Roller Pressure Feeders

TRPF rollers pre-compress and evenly distribute cane before the main crushing mill. This ensures a stable feed and reduces power usage.

Perforated Rollers

Perforated Rollers

Lotus rollers allow juice to escape through holes. This minimizes reabsorption and improves mill extraction by 1–2%.

Role of the Trash Plate In Sugar Mills

The trash plate defines the juice drainage angle and supports the bagasse movement. Proper plate setting ensures efficient juice flow while avoiding choking or bagasse recirculation.

Industrial Sugar Mill Roller’s Settings

Nip Gaps Setting of Industrial Sugar Mill Rollers

Feed Opening

Nip 1 governs cane feeding rate. It is maintained at 18–25 mm, which allows consistent cane entry and initial compression.

Discharge/Work Opening

Nip 2 determines final juice extraction efficiency. Smaller clearances enhance squeezing but must avoid bagasse over-crushing.

Roller Alignment and Geometry

Maintaining Parallelism

Parallel roller alignment prevents uneven load distribution and shell wear. Laser alignment systems are now used for precision setup.

Checking Roll Tram

Roll tram verification ensures uniform clearance along the roller axis. Digital dial gauges and laser tools have replaced the traditional manual checks for higher accuracy.

Hydraulic System Control in Industrial Sugar Mills

Function of Mill Jacks

Hydraulic mill jacks maintain constant load and compensate for cane density variations in real-time.

Relation Between Hydraulic Pressure and Crushing Force

Crushing force is directly proportional to hydraulic pressure. Modern PLC-based control systems regulate mill jacks automatically to maintain consistent pressure and protect the industrial sugar mill roller from overload.

Mean Effective Diameter and Speed Adjustment

The Mean Effective Diameter (MED) affects the linear surface speed and extraction rate. Increasing roller speed slightly enhances throughput but must be balanced against slippage and wear rates.

Maintenance, Hardfacing, and Longevity

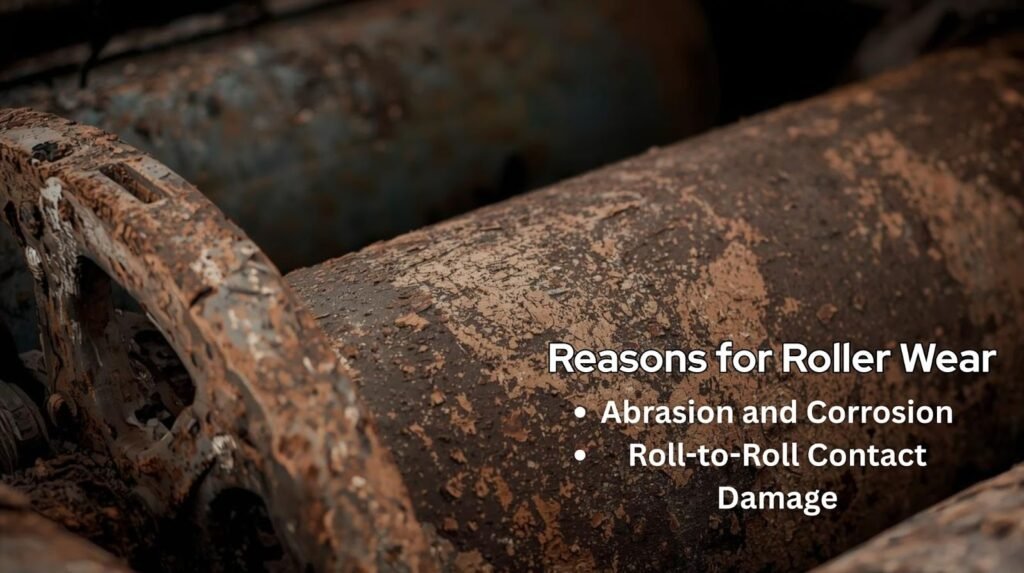

Reasons for Industrial Sugar Mill Roller Wear

Reasons for Industrial Sugar Mill Roller Wear

1. Abrasion and Corrosion

High fiber content and acidic juice lead to corrosion on roller shells, reducing surface life.

2. Roll-to-Roll Contact Damage

Misalignment can cause localized friction and scoring. This damages industrial sugar mill roller’s shell surfaces and bearings.

Industrial Sugar Mill Roller’s Re-grooving and Resurfacing

Diameter Loss Constraints

Shell diameter loss beyond 4–5% affects juice extraction geometry and requires re-shelling or replacement.

Scheduled Recorrugation

Re-grooving intervals are typically planned after every 180–250 working days, depending on cane quality and fiber content.

Industrial Sugar Mill Roller’s Hardfacing Techniques

Industrial Sugar Mill Roller’s Hard-facing Techniques

Hardfacing Alloys

High-chromium carbide electrodes of 60–65 HRC are widely used for re-hardening worn grooves. Modern alloys incorporate Nb and Mo carbides for enhanced resistance.

In-Situ Welding Procedures

In-situ arcing allows roller renovation without dismantling. Controlled preheat of 250–300°C prevents cracking during weld deposition.

Industrial Sugar Mill Roller’s Proactive Maintenance Protocols

Maintenance using vibration and thermal sensors helps monitor bearing wear and shell imbalance. Digital maintenance logs with ERP systems allow tracking roller performance and scheduling downtime effectively.

Order Your Grooved Sugar Mill Roller Now

We are an expert Chinese Sugar Mill Roller Manufacturer. We provide all types of grooved sugar mill rollers: V-Shaped, Helical Grooves, Straight Grooved and perforated rollers. Choose us for your sugar mill rollers for premium quality, competent prices and customer care feedback. Partner with us to enhance your mill’s productivity.

Conclusion

Thus, modern mills use three roller mill configurations, efficient sugar mill structure and accurate mill settings to increase the juice extraction efficiency. Mill owners should have perfect knowledge about the industrial sugar mill roller’s features, types, and settings. Lastly, knowledge about the roller’s resurfacing or regrooving with the hardfacing techniques help increase the roller’s life.