As a top Chinese Sugar Mill Roller Manufacturer, we provide all types of efficient sugar mill rollers. We offer conventional sugar mill rollers, lotus rollers, grooved sugar mill rollers, toothed roller pressure feeders, high duty rollers, fabricated rollers and custom sugar mill rollers. Our roller manufacturing process uses advanced casting technology and cost-effective pricing. We provide additional modifications at a low, feasible price.

Core Roller Types and Performance Specifications

As a top Chinese Sugar Mill Roller Manufacturer, we provide conventional rollers, lotus rollers, grooved roller pressure feeders, toothed roller pressure feeders, high duty rollers, fabricated rollers and custom sugar mill rollers of your choice.

Read More: Sugar Mill Roller Prices and Modification Costs

Conventional Sugar Mill Rollers

Conventional Sugar Mill Rollers

- Function: Standard crushing and primary juice extraction in the main mill stands.

- Key Data Point: Standard shell material typically Cast Iron. They must meet a minimum Brinell Hardness Number of 180-210.

- Material Composition: Forged Steel Shaft with a high-strength Cast Iron shell, ensuring structural integrity under high hydraulic load.

- Estimated Chinese Price Range: $1,500 – $2,000 USD. The prices may vary according to the length, specifications etc.

Read More: Sugar Mill Roller Prices and Modification Costs

Lotus (Perforated) Rollers

Lotus (Perforated) Rollers

- Function: Specifically used as a Top Roller.

- Key Data Point: They increase net juice extraction at the respective mill stand by 10% to 20% compared to non-perforated rolls.

- Design Specificity: Features precisely drilled holes in the shell surface. These rolls require meticulous drilling to maintain shell strength.

- Estimated Chinese Price Range: $2,000 – $3,000 USD

Read More: Sugar Mill Lotus Rollers; Perforated Rollers: Beginner’s Guide

Grooved Roller Pressure Feeders

Grooved Roller Pressure Feeders

- Function: Installed ahead of the main mill stand to compress, de-aerate, and deliver a uniform, high-density cane blanket.

- Key Data Point: Grooved Rollers can increase the crushing capacity by up to 15% by reducing feed slippage and minimizing choking.

- Design Specificity: Features deep, often V-shaped or helical, circumferential grooves for powerful grip and control.

- Estimated Chinese Price Range: $3,500 – $4,500 USD.

Read More: Grooved Sugar Mill Rollers

Toothed Roller Pressure Feeder (TRPF)

Toothed Roller Pressure Feeder (TRPF)

- Function: Used in high-throughput or aggressive feed applications. Especially for dense or non-uniform cane mats.

- Key Data Point: Offers superior positive feeding, ensuring consistent throughput even with fiber content exceeding 14%.

- Material Specification: Teeth are often hardfaced or composed of a specialized alloy steel for superior abrasion resistance.

- Estimated Chinese Price Range: $2,000 – $4,000 USD.

Read More: Sugar Mill Toothed Roller Pressure Feeders: Complete Guide

Custom Sugar Mill Rollers/ Heavy Duty Sugar Mill Rollers

Custom Sugar Mill Rollers/ Heavy Duty Sugar Mill Rollers

- Custom Dimensions: The roller’s diameter, length, and journal sizes are precisely manufactured to fit the mill;s dimensions.

- Tailored Material: The materials which can be chosen contain cast iron, forged steel, or specialized SBR/Ni-Hard alloys. They are chosen based on the mill’s specific operating conditions, such as the required crushing load, cane fiber content, and desired lifespan.

- Optimized Grooving: The groove pitch, depth, and angle are customized.

- Specific Features: May incorporate specialized designs like perforated or internal bleeding rollers to address re-absorption issues.

- Specific Cane Conditions: Unusual or high-fiber cane varieties can be easily managed due to grooving patterns.

- Performance Maximization: Used by mills aiming to squeeze out the highest possible extraction rate or reduce the final bagasse moisture, often through the use of specialized materials and drainage features.

- Pricing: A custom made sugar mill roller costs $2,000 – $5,000 USD per unit.

Read More: Custom Sugar Mill Roller: Specifications, Pricing, and Ordering

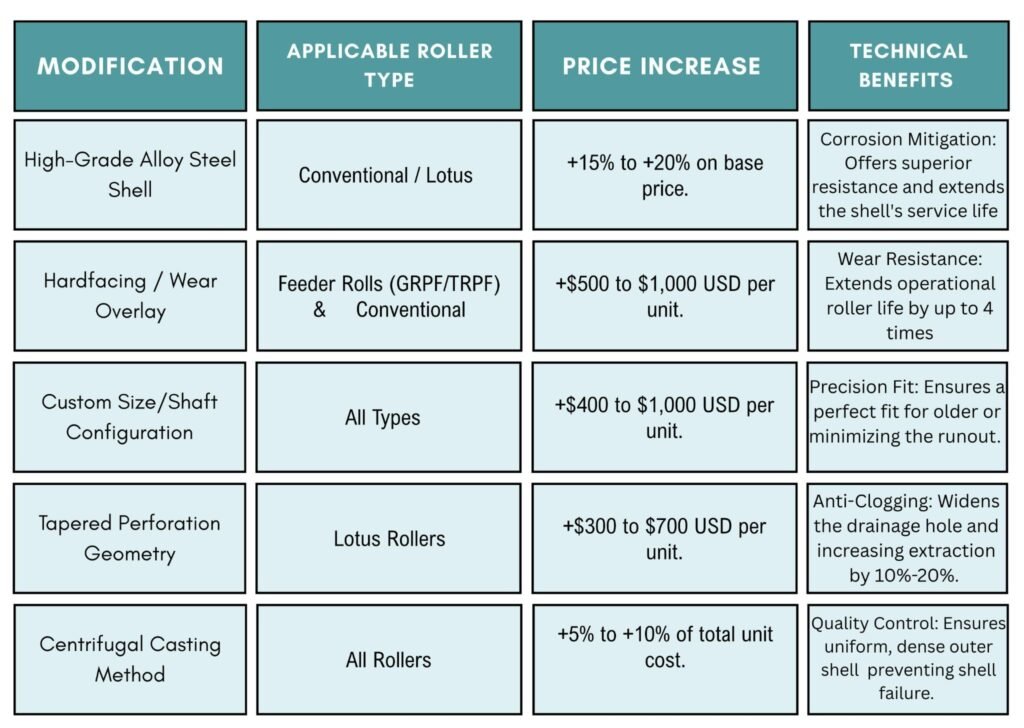

Specific Modifications: Cost Additions and Technical Benefits

For a cheapest Chinese Sugar Mill Roller Manufacturer quote, these are the variables that will add cost but deliver significant long-term benefit.

Specific Modifications: Cost Additions and Technical Benefits

Read More: Sugar Mill Roller Prices and Modification Costs

Order Your Grooved Sugar Mill Roller Now

We are an expert Chinese Sugar Mill Roller Manufacturer. We provide all types of grooved sugar mill rollers: V-Shaped, Helical Grooves, Straight Grooved and perforated rollers. Choose us for your sugar mill rollers for premium quality, competent prices and customer care feedback. Partner with us to enhance your mill’s productivity.

Conclusion

As a Top Chinese Sugar Mill Roller Manufacturer, we provide all types of sugar mill rollers and their modifications at feasible and cheap prices. You can order conventional sugar mill rollers, lotus rollers, grooved sugar mill rollers, toothed roller pressure feeders, high duty rollers, fabricated rollers and custom sugar mill rollers.