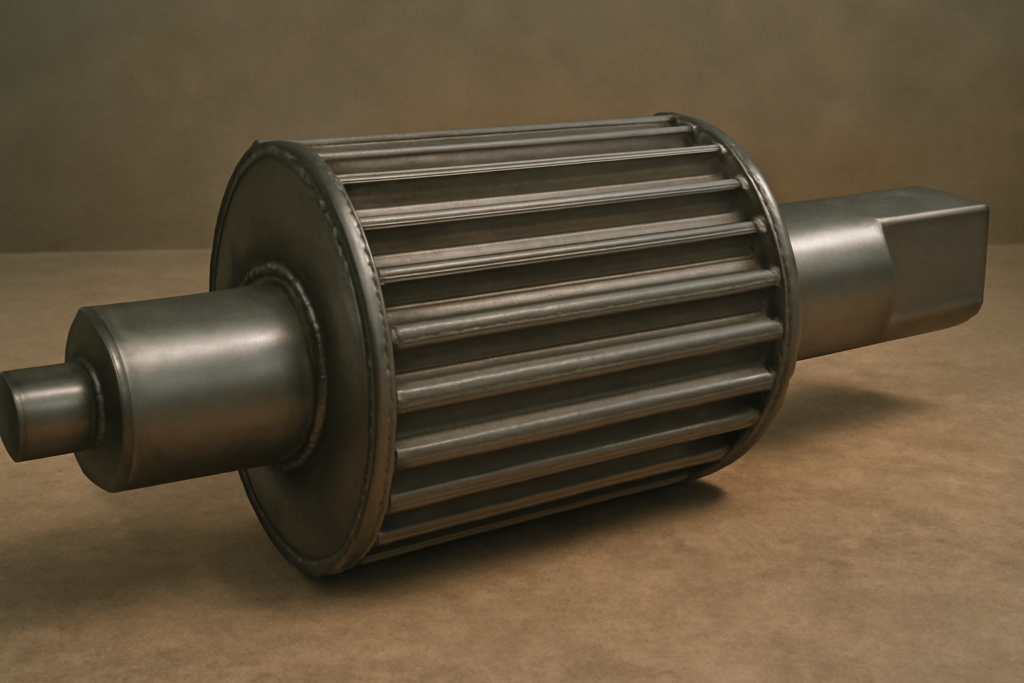

Fabricated Sugar Mill Roller

Our Sugar Mill Roller Equipment company is providing comprehensive and reliable Sugar Mill Roller Equipments to businesses and individuals.

Product Name

Fabricated Sugar Mill Roller

Purpose

The Fabricated Sugar Mill Roller is a high-value, specialized component designed to directly address the pain point of excessive roller weight and offer superior structural flexibility in challenging milling applications. Its primary Purpose is to deliver reliable Primary and secondary juice extraction while reducing the overall machine load on the mill structure and foundation.

Suitable Positions & Configurations for Fabricated Sugar Mill Rollers

This unique construction allows the roller to be used effectively as a substitute for traditional cast rolls due to its weight advantage and structural integrity.

- Mill Type Configurations: Suitable for use across various Roller Mill Type configurations.

- Mill Stand Positions: Can be substituted for the main rolls in any mill stand position, including:

- Top Roll

- Feed Roll

- Discharge Roll

Fabricated Sugar Mill Roller Material

Heavy, Abrasion-Resistant Shell Plate (often using a premium Roll Grade alloy) with Forged Steel Shaft Core

The roller utilizes a heavy, abrasion-resistant shell plate for the working surface, often employing a premium Roll Grade alloy to ensure longevity and wear resistance equivalent to, or better than, conventional rolls.

Fabricated Sugar Mill Roller Material – Casting and Forging

Construction: Advanced Roller Manufacturing Process

- Process: The roller is built via a complex Roller Manufacturing Process that involves welding the shell plate onto the shaft.

- Component Manufacturing: This process utilizes advanced Technicals – Casting and Forging for the individual components (shell plate material and shaft).

- Fusion: The shell is fixed to a large diameter, precision-machined Forged Steel Roller Shaft using meticulous, certified welding techniques to ensure superior structural integrity.

Performance

- Wear Resistance: The construction ensures exceptional Wear Resistance from the shell plate.

- Structural Integrity: The fabricated, welded structure provides superior structural flexibility and integrity while achieving weight reduction.

Heat Treatment of Fabricated Sugar Mill Roller

Shaft Reinforcement: The Forged Steel Roller Shaft is treated via specific Heat Treatment for maximum toughness, ensuring the critical core component can withstand dynamic operating stresses.

Key Dimension -Diameter and Length, Tolerance, Weight

Precision and Fitment

We guarantee zero Fitment Issues by adhering to international Standard specifications for all dimensions.

Dimension | Requirement | Tolerance |

Diameter and Length | Custom requirements defined by mill specifications | Ultra-Precise Tolerance |

Critical Fits | Matched exactly to client’s mill parameters | Ultra-Precise Tolerance e.g. 0.05 mm |

Weight | Significantly reduced compared to solid cast rolls | N/A |

Ultra-Precise Tolerance

We deliver ultra-precise tolerance of 0.05 mm across all Diameter and Length requirements to guarantee seamless integration and high-speed operational stability.

Inspection & Quality

Quality

This unique roller offers high value, ensuring exceptional Wear Resistance and structural integrity while providing competitive Sugar Mill Roller Prices for a specialized component.

QA/QC Inspectors

Our stringent, certified QA/QC Inspectors verify the material composition of the shell and shaft, inspect the critical dimensional tolerances, and specifically test the integrity of the welded fabrication joints.

Machinery Test Report

This essential investment is backed by a detailed Machinery Test Report providing full assurance on:

- Material certifications for the shell plate and forged shaft.

- Full documentation of the specific welding and Heat Treatment processes used.

- Records confirming adherence to ultra-Precise Tolerance.

- Non-Destructive Testing (NDT) results for the weld seams.

Industry Applications of Fabricated Sugar Mill Roller

- Primary and secondary juice extraction in mills with weight constraints.

- Applications requiring high structural flexibility and impact resistance.

- Demanding Industry Applications where overall machine load reduction is critical.