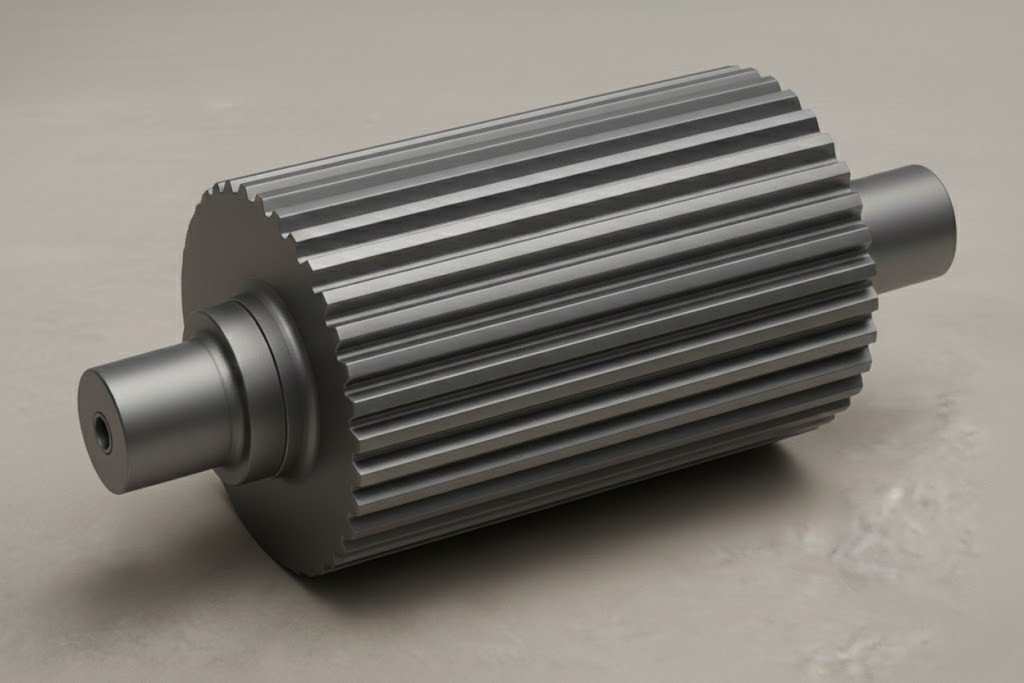

Iron Cast Shell Sugar Mill Roller

Our Sugar Mill Roller Equipment company is providing comprehensive and reliable Sugar Mill Roller Equipments to businesses and individuals.

Product Name

Cast Iron Shell Roller

Purpose

The Cast Iron Shell Roller is the economical and reliable solution for foundational Primary juice extraction. Its primary purpose is to provide dependable milling performance while directly addressing the pain points of high capital cost and general premature wear often experienced in standard milling operations.

Suitable Positions & Configurations for Cast Iron Shell Sugar Mill Rollers

The CISR is optimally utilized where operational stresses are manageable, providing reliable crushing without the premium cost of specialized alloys.

- Roller Mill Type Configurations: Ideally suited for smaller capacity Roller Mill Type configurations.

- Mill Stand Positions: Optimally utilized in later mill stand positions (e.g., final discharge rolls) where extreme pressure and abrasion are not the primary concern.

Cast Iron Shell Sugar Mill Roller Material

Standardized, High-Quality Cast Iron Shell with Forged Steel Shaft Core

The roller utilizes a standardized, high-quality Roll Grade of Cast Iron—a cost-effective Custom Casting Material—for the shell. This shell material provides essential Wear Resistance for its targeted applications.

Cast Iron Shell Sugar Mill Roller Material Casting and Forging

Shell: Cost-Effective Custom Casting Material

- Material: Standardized, high-quality Cast Iron.

- Process: Manufactured using a documented Roller Manufacturing Process that adheres to stringent quality controls for consistency and reliability.

- Design: The Sugar Mill Roller Design features a standard grooving profile and precise Sugar Mill Roller Arcing to maintain consistent feeding and reliable performance.

Shaft: Durable Forged Steel Roller Shaft

Core Component: The cost-effective shell is fused to a durable Forged Steel Roller Shaft.

Heat Treatment of Cast Iron Sugar Mill Roller

Process: The Forged Steel Roller Shaft is subjected to specific Heat Treatment to ensure core toughness and structural integrity against the stresses encountered in foundational milling.

Key Dimensions-Diameter and Length, Tolerance, Weight

Precision and Fitment

We guarantee zero Fitment Issues by adhering to international Standard specifications for all dimensions.

Dimension | Requirement | Tolerance |

Diameter and Length | Varies by mill specification | Tight Tolerance |

Critical Fits- Journal/Bore | Matched to bearing specifications | Tight Tolerance e.g. 0.1 mm |

Weight | Full details provided upon request | N/A |

Tight Tolerance

We deliver tight Tolerance, e.g. 0.1 mm, across all Diameter and Length requirements, ensuring compatibility and stable operation.

Inspection & Quality

Quality

This commitment to High Quality and maximized value ensures a dependable component offering competitive Sugar Mill Roller Prices for Industry Applications.

QA/QC Inspectors

Quality assurance is verified by stringent QA/QC Inspectors who validate the adherence to the standardized material composition and dimensional specifications.

Machinery Test Report

The dependability of this component is verified by a documented Roller Manufacturing Process and inspection records, providing quality assurance. (Specific Machinery Test Report details were not provided, but documentation of the process is confirmed).

Industry Applications of Iron Cast Sugar Mill Roller

- Foundational Primary Juice Extraction

- Milling in smaller capacity Roller Mill Type configurations

- Later mill stand positions e.g. final discharge rolls