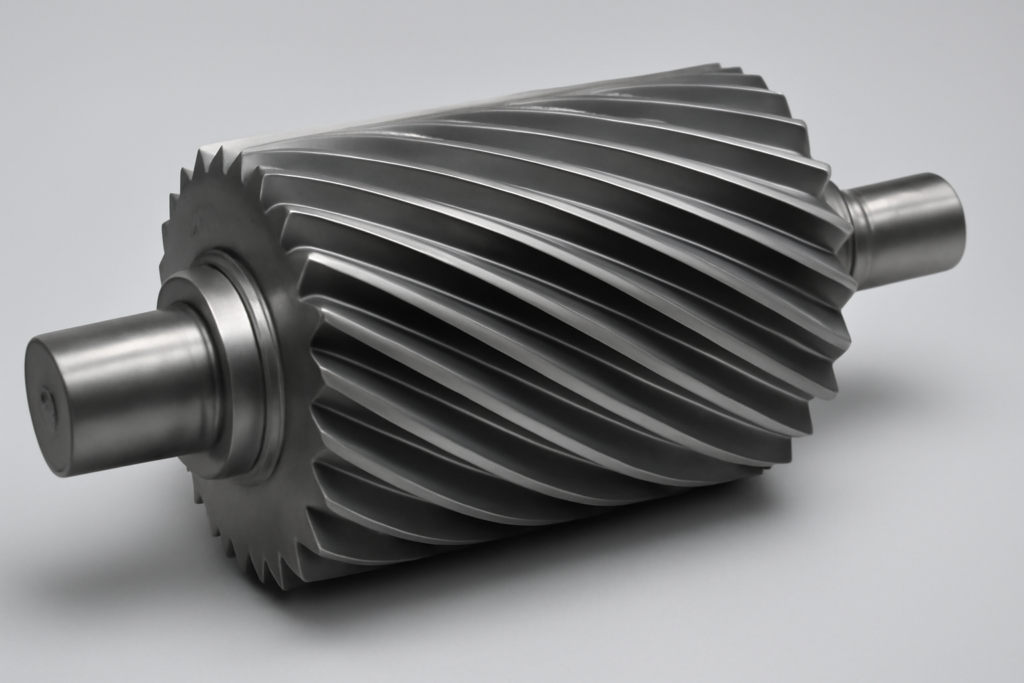

SRB Alloy Sugar Mill Roller

Our Sugar Mill Roller Equipment company is providing comprehensive and reliable Sugar Mill Roller Equipments to businesses and individuals.

SBR Special Alloy Roller

Product Name

SBR Special Alloy Roller

Purpose

The SBR Special Alloy Roller is the premium solution designed to directly combat the severe pain points of rapid component erosion and extreme premature wear caused by high-abrasion milling conditions. Its purpose is to deliver Primary juice extraction in the harshest environments with maximized wear resistance and superior longevity.

Suitable Positions & Configurations for SBR Alloy Roller

This specialized roller is engineered for the most demanding service conditions within the mill train.

- Roller Mill Type Configurations: Designed for use across high-capacity Roller Mill Type configurations.

- Mill Stand Positions: Specifically engineered for Primary juice extraction in the most demanding positions, especially the Top and Feed Rolls.

SBR Alloy Roller Material

Proprietary Roll Grade SBR Custom Casting Material Shell with High-Strength Forged Steel Shaft Core

This component utilizes our proprietary Roll Grade SBR Custom Casting Material—a proprietary high-performance, non-standard material—for the shell. This advanced alloy is scientifically proven to deliver exceptional Wear Resistance and superior longevity.

SBR Alloy Roller Material – Casting and Forging

Shell: Proprietary SBR Custom Casting Material

- Material: Proprietary Roll Grade SBR Custom Casting Material.

- Performance: Scientifically proven to deliver exceptional Wear Resistance and superior longevity.

- Process: The robust shell is fused via precise Technicals – Casting and Forging processes tailored to the specific metallurgical requirements of the SBR alloy to maintain structural integrity.

Shaft: High-Strength Forged Steel Roller Shaft

- Core Component: The robust shell is fused onto a high-strength Forged Steel Roller Shaft.

Heat Treatment for SRB Alloy Roller

Process: The shaft and the specialized SBR shell are reinforced by a tailored Heat Treatment protocol designed for maximum toughness and to optimize the alloy’s microstructure for supreme wear resistance.

Key Dimensions-Diameter and Length, Tolerance, Weight

Precision and Fitment

We guarantee zero Fitment Issues by adhering to international Standard specifications for all dimensions.

Dimension | Requirement | Tolerance |

Diameter and Length | Custom requirements defined by mill specifications | Ultra-Precise Tolerance |

Critical Fits (Journal/Bore) | Matched exactly to mill parameters | Ultra-Precise Tolerance e.g. 0.05 mm |

Weight | Full details provided in the test report | N/A |

Ultra-Precise Tolerance

We deliver ultra-precise tolerance e.g. 0.05 mm across all Diameter and Length requirements, which is critical for smooth, high-speed operation under severe load.

Inspection & Quality

Quality

This commitment to High Quality and maximized service life justifies competitive Sugar Mill Roller Prices for the most challenging Industry Applications.

QA/QC Inspectors

Our commitment is verified by stringent QA/QC Inspectors who validate the adherence to the proprietary SBR alloy composition and the ultra-precise dimensional tolerances.

Machinery Test Report

The roller’s superior performance is verified by specific Machinery Test Report data on its structural integrity and Surface Hardness, providing evidence of its exceptional quality.

Industry Applications

- Primary Juice Extraction in High-Capacity Mills

- Applications subject to high-abrasion milling conditions

- Most challenging Industry Applications where standard materials fail prematurely