Grooved Roller Pressure Feeders

Our Sugar Mill Roller Equipment company is providing comprehensive and reliable Sugar Mill Roller Equipments to businesses and individuals.

Product Name

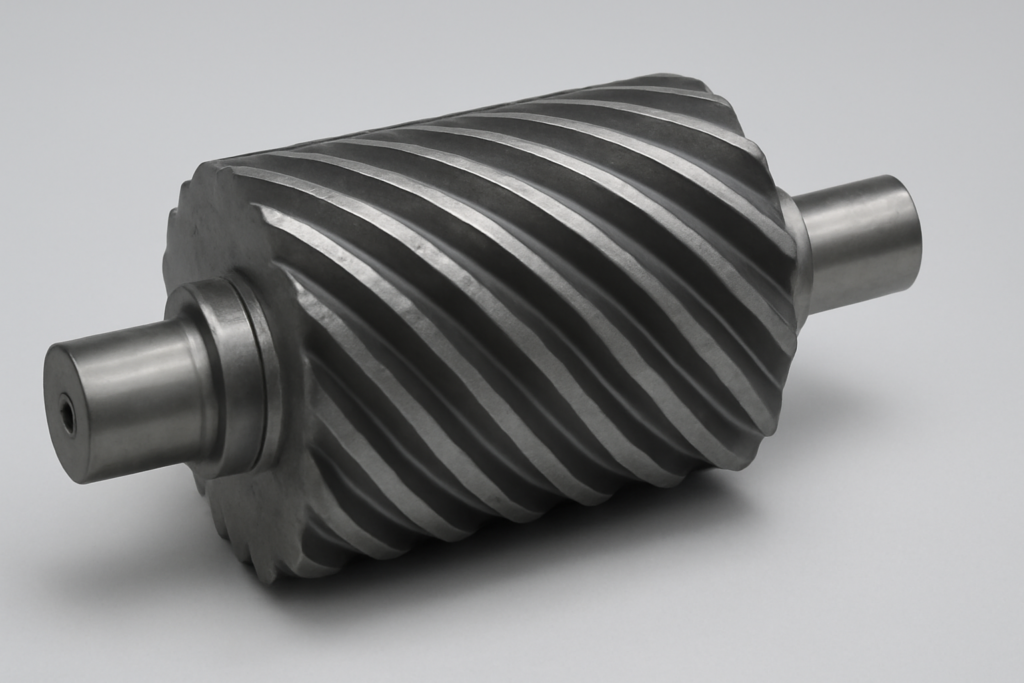

Grooved Roller Pressure Feeder

Purpose

The Grooved Roller Pressure Feeder (GRPF) is a highly specialized component engineered to solve the critical pain points of inconsistent cane feeding and low mill throughput, particularly in high-capacity milling environments. Its primary purpose is pre-compression and forced feeding of the cane blanket directly into the main mill stands, overcoming issues of slippage and choke-feeding.

Suitable Positions & Configurations for Grooved Sugar Mill Rollers

The GRPF is designed to enhance the feeding capacity and efficiency of the entire mill train.

- Mill Type Configurations: Primarily for use in high-capacity Roller Mill Type configurations.

- Mill Stand Positions: Specifically engineered for the position where pre-compression is needed, most often replacing or augmenting the traditional Feed Roll position before the main crush zone.

Grooved Sugar Mill Roller Material

Premium Roll Grade Alloy Shell with Forged Steel Shaft Core

The component utilizes a premium Roll Grade alloy shell to withstand the aggressive forces of pre-compression while ensuring excellent wear characteristics. The inner structure is a robust Forged Steel Roller Shaft.

Grooved Roller Pressure Feeder Material – Casting and Forging

Design: Aggressive Grooving and Pre-Compression

- Unique Sugar Mill Roller Design: The unique design features deeper, aggressive grooving and precise Sugar Mill Roller Arcing.

- Function: This geometry is specifically engineered to maximize grip and material density in the cane blanket before it enters the main crush, thereby facilitating the forced feeding required for high throughput.

Components and Construction

- Shell and Shaft: The component employs a premium alloy shell and a robust Forged Steel Roller Shaft—both of which are manufactured using specialized casting and forging techniques to ensure strength against pre-compression forces.

Heat Treatment of Grooved Rollers

- Process: Both the premium Roll Grade alloy shell and the robust Forged Steel Roller Shaft are subjected to specific Heat Treatment. This process is crucial to ensure the components can withstand the aggressive forces and high stresses of pre-compression without premature failure.

Key Dimensions-Diameter and Length, Tolerance, Weight

Precision and Fitment

This crucial Core Component is manufactured to international Standard to guarantee zero Fitment Issues.

Dimension | Requirement | Tolerance |

Diameter and Length | Defined by required pre-compression capacity and mill size | Ultra-Precise Tolerance |

Critical Fits | Matched to mill stand and bearing specifications | Ultra-Precise Tolerance (e.g., $\pm 0.05 \text{ mm}$) |

Weight | Full details provided in the test report | N/A |

Ultra-Precise Tolerance

We deliver ultra-Precise Tolerance e.g. 0.05 mm across all Diameter and Length requirements, which is vital for maintaining the precise clearances needed for effective forced feeding.

Inspection & Quality

Quality

Our commitment to High Quality ensures this component maximizes efficiency and provides competitive Sugar Mill Roller Prices for challenging Industry Applications.

QA/QC Inspectors

Our stringent, certified QA/QC Inspectors verify the aggressive grooving profile, the metallurgical integrity of the specialized alloys, and the precise dimensional accuracy required for forced feeding.

Machinery Test Report

This investment is verified by a detailed Machinery Test Report providing full assurance on:

- Material composition and properties.

- Documentation of the specific Heat Treatment applied.

- Records confirming adherence to ultra-Precise Tolerance.

Industry Applications of Grooved Rollers

- High-capacity Sugar Milling

- Applications requiring consistent, forced feeding

- Challenging Industry Applications focused on maximizing throughput