Mill crushing rollers are used to crush sugarcane fibres to extract maximum juice. Sugar mill crushers start the crushing process from cane feeding, followed by the sugar mill crushing zones. Sugar juice and bagasse are then collected in collection zones too. Lastly, the imbibition process is used in modern mills. Modern mills now use optimised pressure control systems, IOT sensors, predictive analysis along with energy efficient designs to increase the sugar mill crushers efficiency.

Pre-Milling Operations: Preparing the Cane for Sugar Mill Crushers and Rollers

Sugar Cane Pre-Crushing Preparations

- Sugarcane Harvesting and Transportation

The sugarcane must be transported quickly after the harvest to prevent sucrose degradation. The cane’s quality, highly affects the performance of mill crushing roller and sugar mill crusher to perform optimally. Cane that is too old or degraded will reduce the efficiency of juice extraction.

- Cane Yard Operations

The sugarcane is washed thoroughly to remove soil and trash. Magnetic separators protect the sugar mill crushers from metal debris. The cane is then leveled and prepared for crushing.

Sugar Cane Crushing Process Step by Step

Sugar Cane Crushing Process in Sugar Mills

Stage 1: Cane Feeding into Mill Crushing Rollers

The sugarcane crushing process starts when prepared cane enters the mill. Before crushing begins, the sugarcane is cleaned and cut into small pieces called billets. These pieces are usually 15-30 cm long, making them easier to handle and crush.

How the feeding works: Conveyor belts carry the cut cane pieces and drop them onto the first set of crushing rollers. These rollers are huge – about 75-90 cm wide and 150-210 cm long. They spin slowly in opposite directions to grab the cane and pull it through the mill. The rollers turn at just 3-6 rotations per minute to make sure the cane feeds evenly without getting stuck.

Controlling the feed rate is very important. Modern sugar mills use automatic systems that watch how hard the motor is working. If the motor is working too hard (meaning too much cane is going in), the system slows down the feed. If the motor has an easy load, more cane is fed in. This keeps everything running smoothly. Most mills can handle 250-500 tonnes of cane every hour.

The feeding rollers have special grooves cut into their surface. These grooves help grip the cane and pull it into the crushing area. The grooves are cut at angles between 30-45 degrees. As the rollers grab the cane, these grooves start breaking the tough outer layer of the cane stalks. This prepares the cane for the main crushing step where the juice comes out.

Stage 2: First Pressure Zone – Hydraulic Pressures and Mill Crushing Rollers

When the cane enters the first pressure zone, the real crushing begins. The mill has sets of three or four rollers working together. The top roller pushes down while the bottom rollers crush the cane from below.

Hydraulic pressure systems provide the crushing power. These systems use special fluids and gases to push down on the top roller with enormous force – between 500 and 1500 tons. To picture this, imagine 100 to 300 elephants standing on top of the cane! The hydraulic system has several advantages:

- It keeps the pressure steady even when thick and thin cane pieces go through

- It protects the mill by letting the roller lift up if metal or rocks accidentally get mixed in

- Operators can adjust the pressure instantly based on the type of cane being crushed

The pressure applied to the cane is usually 1.5-2.5 kg for every square centimeter of roller surface. Getting this pressure right is critical. Too little pressure means poor juice extraction. Too much pressure can make the rollers slip, waste energy, and damage the equipment.

The sugar mill crusher breaks open the cane cells using squeezing and twisting forces. Sugarcane is made up of tiny cells filled with sweet juice. These cells are surrounded by tough walls made of fiber. When the rollers squeeze the cane, the cell walls break and the juice flows out. In the first mill, this crushing releases 50-60% of all the juice in the cane.

Temperature is kept between 30°C and 40°C during crushing. This temperature range matters because:

- Below 30°C: The juice gets thick and sticky, making it hard to extract

- Above 40°C: Bacteria grow faster and can damage the sugar quality

- The friction from crushing naturally creates heat, which helps keep the temperature in the right range

The juice extracted in this first crushing is called “first mill juice.” It has the most sugar (12-16% sugar content) and the fewest impurities. This juice drips through holes in metal plates under the rollers. It collects in a container and gets pumped to the next stage of sugar making.

Stage 3: Secondary Compression with Mill Crushing Rollers

After the first crushing, the squeezed cane (now called “bagasse”) still has juice trapped inside. It moves to additional mills – usually 3-5 more crushing units lined up in a row. Each mill extracts more juice using similar crushing methods.

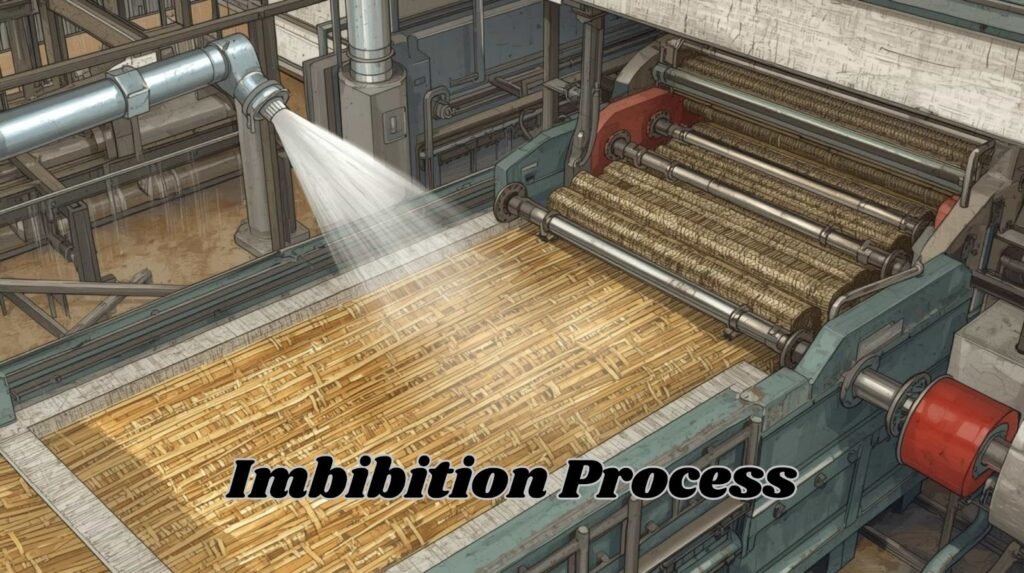

The imbibition process: Before each additional mill, hot water is sprayed onto the bagasse. This hot water (70-80°C) helps wash out the remaining juice. About 25-30% of the cane’s weight in hot water is used. The hot water soaks into the crushed fibers and dissolves the trapped juice, making it easier to squeeze out.

The secondary mills use slightly different pressures:

- 2nd mill: 1200-1400 tons of pressure

- 3rd mill: 1100-1300 tons of pressure

- 4th mill: 1000-1200 tons of pressure

- 5th mill (if there is one): 900-1100 tons of pressure

The pressure decreases at each mill because there’s less juice to extract and the bagasse becomes more packed with fiber. Each mill extracts another 10-15% of the remaining juice.

Roller design changes in the later mills. The first mill has deep grooves (20-25 mm deep) that aggressively grab the cane. Later mills have shallower grooves (15-20 mm deep) that work better with the compressed, fiber-heavy material.

Juice quality changes as it goes through the mills:

- 1st mill juice: 12-16% sugar, very clean

- 2nd mill juice: 8-12% sugar, slightly less clean

- 3rd mill juice: 5-8% sugar, more impurities

- Final mill juice: 2-4% sugar, most impurities (mostly from the wash water)

The juice from all the mills gets mixed together and sent to the cleaning process. A well-run mill system extracts 94-97% of the sugar, leaving only 3-6% in the final bagasse.

Moisture content drops as the bagasse goes through each mill:

- After 1st mill: 70-75% moisture

- After 2nd mill: 60-65% moisture

- After 3rd mill: 55-60% moisture

- After final mill: 48-52% moisture

Reducing the moisture is important because drier bagasse burns better as fuel in the factory’s boilers.

Stage 4: Bagasse Discharge and Crusher Efficiency

The final stage involves removing the spent bagasse from the last mill and checking that everything is working properly.

How bagasse is discharged: As the bagasse leaves the final mill, it passes over a smaller discharge roller and falls onto a conveyor belt. This roller is smaller (60-75 cm wide) and spins a bit faster than the crushing rollers. This prevents the bagasse from piling up. The bagasse comes out as a compressed mat of fibers.

The sugar mill crusher discharges bagasse with 48-52% moisture, which is ideal for several reasons:

- At 52% moisture: The bagasse has enough moisture to prevent dust problems during handling and burns completely in boilers

- At 48% moisture: The bagasse has excellent heat value (1,850-2,200 calories per kilogram) and shows that extraction was very efficient

Bagasse characteristics when discharged:

- Fiber pieces: 10-30 mm long (much shorter than the original 150-300 mm stalks)

- How dense it is: 120-180 kg per cubic meter (loose), 200-300 kg per cubic meter (packed)

- What it’s made of: About half cellulose (fiber), the rest is other plant materials

- Temperature: 45-55°C (warm from friction and hot water)

How bagasse is used: Conveyor belts carry the bagasse to:

- Boiler house (main use): 70-80% gets burned immediately to make steam that powers the factory

- Storage buildings: 15-25% is saved for backup fuel

- Other uses: 5-10% might be sold for making paper, particle board, animal feed, or compost

Checking crusher efficiency means constantly monitoring several things:

How well extraction is working:

- Sugar left in bagasse: Should be less than 2% (on dry basis)

- Overall extraction: Should be above 96% of total sugar in the cane

- Fiber content: Should stay at 44-48% (on dry basis)

How efficiently things are running:

- Electricity used: Typically 12-18 kilowatt-hours per ton of cane

- Hydraulic pressure: Should stay steady, changing less than 50 tons

- Mill capacity: Should run at 90-100% of designed speed

- Hot water amount: Should be 25-30% compared to fiber weight

Mill performance checks:

- Roller condition: Regular checks for wear and groove depth (regrooved when below 12-15 mm)

- Bearing temperature: Watched constantly (alarm at 70°C, shutdown at 80°C)

- Pressure distribution: Should be even across the roller length

- Feed rate steadiness: Should not vary more than 15%

Ways to improve efficiency:

- Scheduled maintenance: Mills stop every 3-5 days for 2-4 hours to inspect rollers, replace worn parts, and clean screens

- Computer systems: Modern mills use computers that automatically adjust feed rate, pressure, and hot water based on current conditions

- Laboratory testing: Samples of juice and bagasse are tested every 2 hours to check performance

- Energy recovery: Using waste heat from other processes to warm the wash water, saving energy

Performance goals for a good crushing system:

- Total extraction: 96-97%

- Sugar in dry bagasse: 1.5-2.0%

- Final bagasse moisture: 48-50%

- Mill running time: 85-90% during crushing season

- Crushing rate: 5-7 tonnes per square meter of roller per hour

Continuous monitoring of these factors ensures the mill runs at its best. This maximizes sugar recovery while producing bagasse that’s perfect for fuel. Modern sugar mills are designed to make enough steam and electricity from bagasse to run the entire factory. Some mills even make extra electricity that they can sell to the power grid.

Stage 5:Imbibition Process

Imbibition Process in Sugar Mills

The imbibition process involves adding water to the bagasse to extract the remaining sugar. This starts by spraying hot water of 70 C onto the bagasse just before the final mill. The very weak, diluted juice extracted by this last mill is then immediately recycled backward to wash the bagasse entering the mill before it. This recycling continues, ensuring that the increasingly richer juice is used to wash increasingly richer bagasse. This counter-flow creates an efficient “sugar recovery ladder.”

It ensures uniform distribution to maximize juice extraction. An optimized imbibition ratio of 25-30% can increase sugar recovery by 1-3%.

Performance Monitoring of Mill Crushing Rollers and Sugar Mill Crushers

Critical Parameters for Roller and Crusher Performance

Hydraulic pressure, feed rate, roller speed, and imbibition water flow all influence the performance of mill crushing rollers and sugar mill crushers. Monitoring these variables ensures that extraction efficiency remains high.

Performance Indicators

Key performance metrics show extraction efficiency of 94-97%, with the bagasse moisture of 48-52%, and the residual sugar content in the bagasse of less than 2%. Present efficient use of sugar mill crushers and mill crushing rollers.

Order Your Grooved Sugar Mill Roller Now

We are an expert Chinese Sugar Mill Roller Manufacturer. We provide all types of grooved sugar mill rollers: V-Shaped, Helical Grooves, Straight Grooved and perforated rollers. Choose us for your sugar mill rollers for premium quality, competent prices and customer care feedback. Partner with us to enhance your mill’s productivity.

Conclusion

Mill crushing rollers start the process by initial cane feeding, followed by the sugar mill crushing zones. Finally, modern sugar mills provide efficient juice and bagasse collection zones along with the imbibition processes. Modern mills now use optimised pressure control systems, IOT sensors, predictive analysis along with energy efficient designs to increase the sugar mill crushers efficiency